ADVFORGE CORPORATION

宜德股份有限公司

Founded in 2023, ADVFORGE has a management team with 20 years of experience in magnesium alloy, magnesium-lithium alloy (LZ-91), aluminum alloy forging and CNC machining technology. Initially focused on OEM production, we now specialize in medical, aerospace, automotive parts processing and various sheet metal hardware products.

Achieve Ourselves

Benefit All Beings

Create Win-Win Outcomes

Business Philosophy

Trade Tool Auto Group(元創集團) - ADVFORGE Corporation integrates magnesium alloy and magnesium-lithium alloy forging with CNC machining for medical, aerospace, military, and automotive components, achieving lightweight and high-strength requirements. We pursue excellence and sustainable operations, committed to providing reliable product services and quality.

Customer Type

Magnesium, Aluminum & Lithium Alloy Forging and Stamping Technology Advantages

Step1

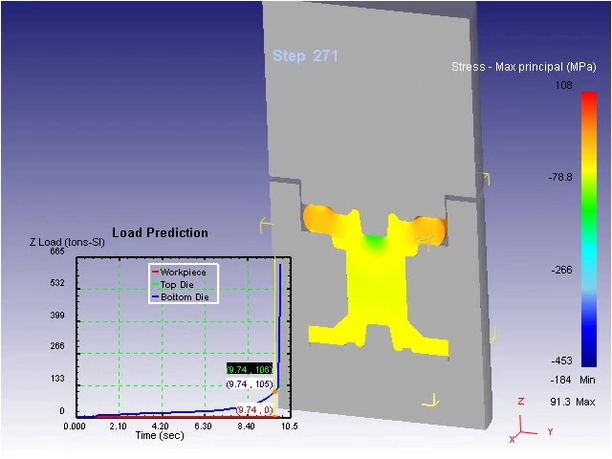

Material Forming Simulation Design CAE

-

High efficiency single-forging design

-

Closed die cavity design saves materials

-

High stability of forged products

-

High production stability with constant temperature dies

Step2

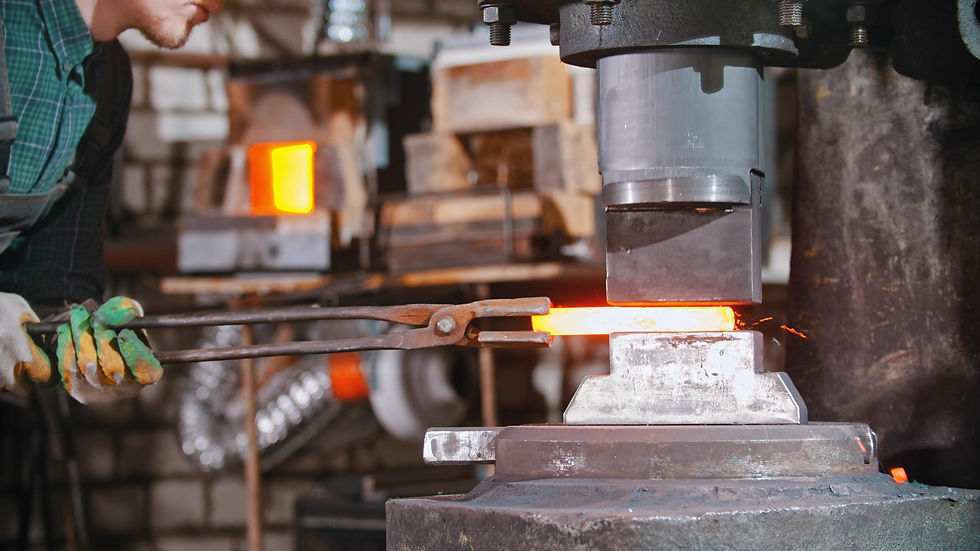

Precision Forging Die Design and Forging Production

-

Variable pressure forging with high fluidity

-

High precision product forming

-

Minimal deformation after forging

-

Low noise, low vibration, high stability

Step3

Precision Constant Temperature Water-Cooled CNC Machining

-

Products less prone to oxidation

-

Stable production quality

-

Minimal thermal deformation during machining

Example Processing Video

-

Large Drum Forging Video

-

Second Stage Forging Video of Large Drum

-

Wheel Rim Forging Video

-

Laptop Case Forging Video

-

X-ray Machine Panel Forging Video

Work Flow

01.

Simulation

- Forging blank forming

- Blank material selection

- Forging tonnage

02.

Die Design

- Trial/Mass production dies

- Die manufacturing

03.

Forging Processing

-Simulation verification

- Die modification

- Forging conditions

04.

Mechanical Processing

- Final dimensional machining

05.

Surface Treatment

- Various surface treatments

Machinery & Measuring Equipment

Apllication

Mg Alloy

Wearable Exoskeleton

請按一下此處編輯文字,寫下要展示的資訊。

Mg Alloy

Lightweight Drone Helicopter Shaft

請按一下此處編輯文字,寫下要展示的資訊。

Mg Alloy

Portable X-Ray Machine

請按一下此處編輯文字,寫下要展示的資訊。

Mg Alloy

Automotive Brake Caliper

請按一下此處編輯文字,寫下要展示的資訊。

Mg Alloy

Wheels

請按一下此處編輯文字,寫下要展示的資訊。

Mg Alloy

High-End Graphics Machine Casing

請按一下此處編輯文字,寫下要展示的資訊。

Developable Application Products

Electric Vehicle Components

Battery Modules

Small Reactors

Wind Power Heat Sinks

Ultrasonic Component Modules

Eyewear/Night Vision Frames

Drone Components

Corporate Client List

|  |

|---|

ISO 9001.2013 Certification

ADVFORGE magnesium alloy forging has long been trusted by customers

ADVFORGE was founded in 2023, initially focusing on OEM production. We now primarily engage in the processing and manufacturing of medical, aerospace, and automotive components, as well as various sheet metal and hardware products. We uphold the philosophy of pursuing excellence and sustainable operations, committed to providing customers with reliable product services and quality.

In 2023, ADVFORGE will introduce magnesium alloy and aluminum alloy forging and CNC machining technologies, integrating with Yuanchuang Group's automotive design, development, and manufacturing processes to provide comprehensive one-stop product services. This not only ensures superior quality but also saves time and costs for our customers.

ISO 9001 Certified: Establishing potential customers' trust in our standardized systems and process capabilities.